We are constantly introducing improvements to our processes, and we encourage our team to do so. It's in our DNA.

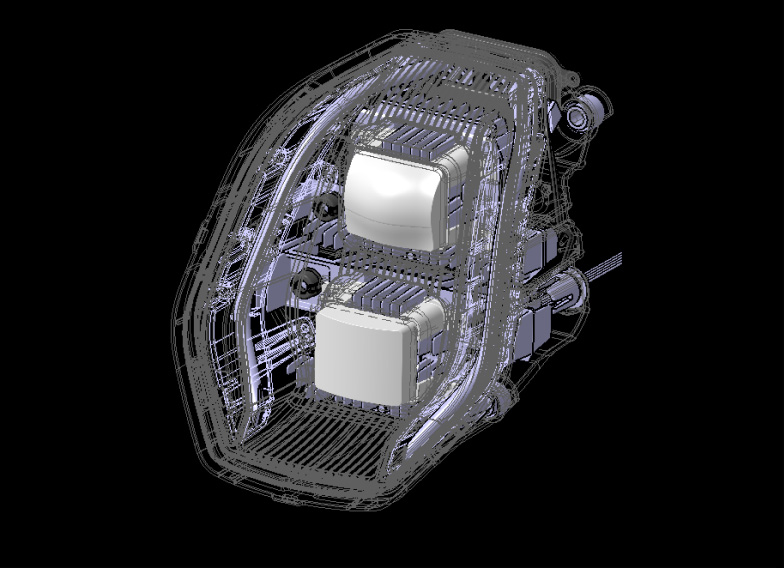

Custom lighting design and engineering

Based on a solid foundation with over 40 years of experience, we are able to provide custom lighting design and engineering services for any application.

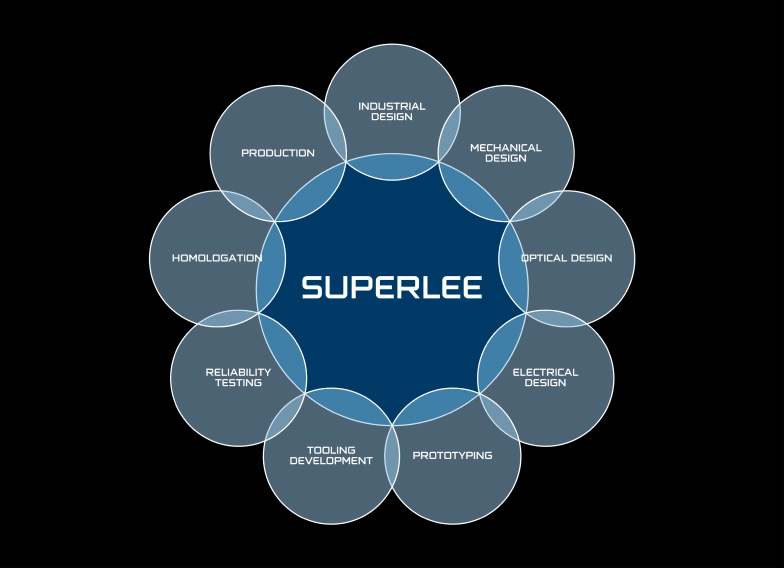

Product development process

We consider ourselves an extenstion to our customers' product developement team. Our development process can begin as early as styling design, followed by lighting design, tooling development, homologation, reliability testing, and finally into production.

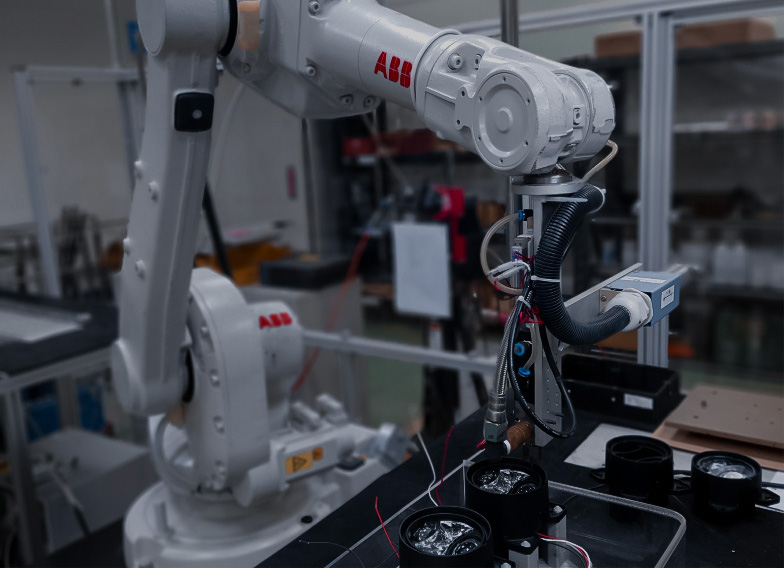

Multi-joint robot glue dispenser

Our gluing process relies on 6 axis robot that enables us to come up with sophisticated glue channel design.

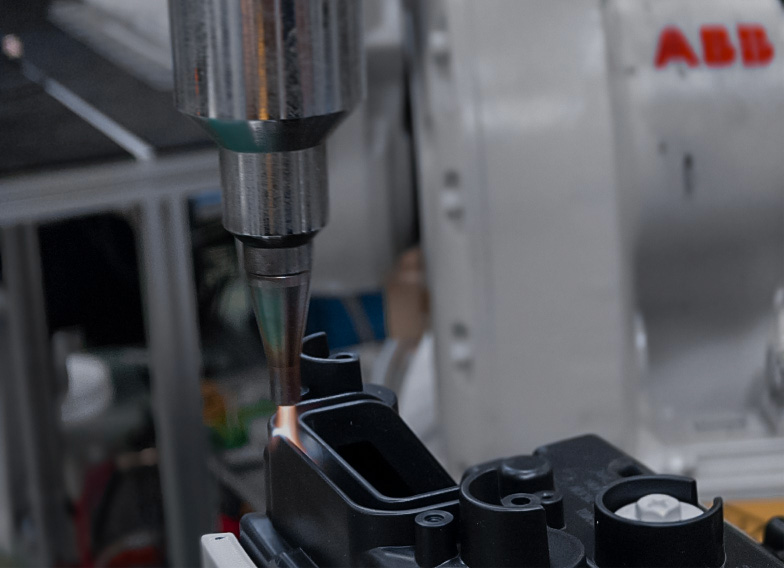

Plasma surface etching

Our plasma etching equipment is integrated into our gluing system and mounted on the 6 axis robot, increasing the bonding of glue to its substrate.

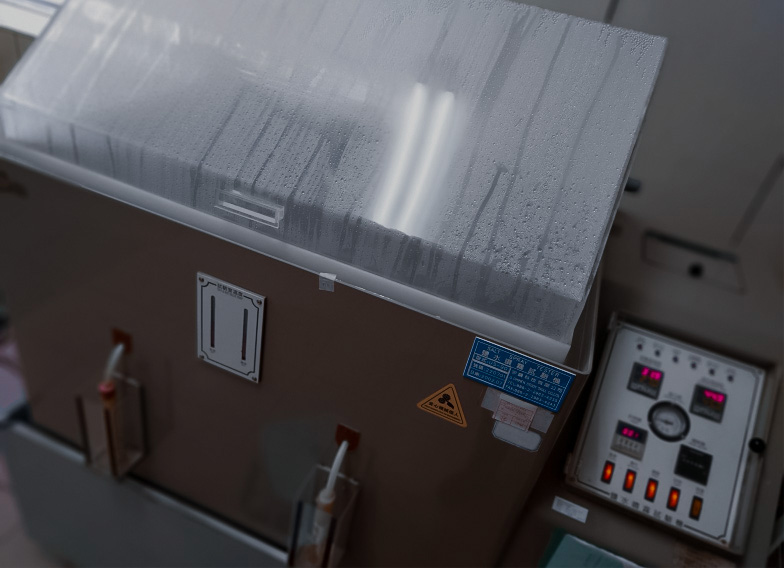

Reliability testing

We have a set of internal reliability test standards that all new products should pass before being released for production. We can also incorporate additional test standards required by our customers.

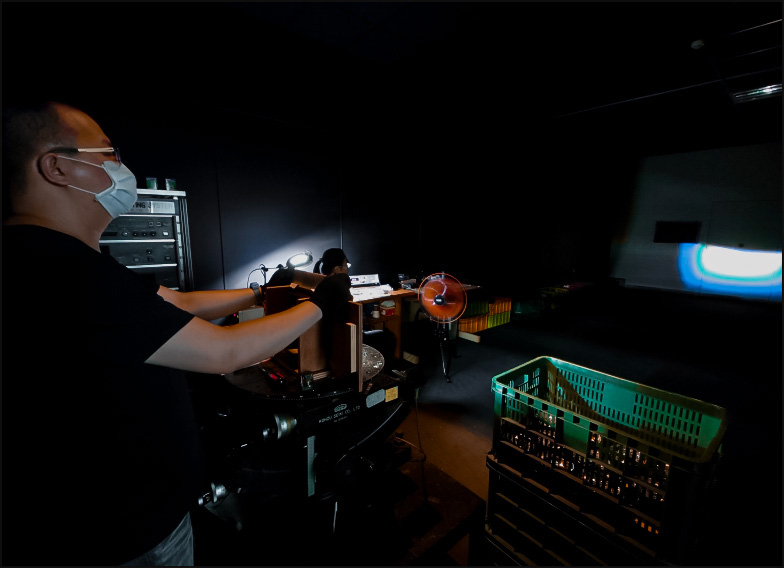

Photometric measuring

Our in-house dark room equipped with goniophotometer allows us to perform photometric measurements internally.

ESOP guided assembly

Our assembly line is Electronic SOP guided, which allows our operators to check and confirm procedures and watch for critical points during assembly process to minimize mistakes.

3D printed production fixture

We incorporate our in-house 3D printed fixtures during our assembly process to increase assembly precision and reduce fixture development time.

SPC controlled glue weight monitoring system

Glue weight monitoring system is part of our gluing system, taking measurement of the glue weight for each and every light that comes through.